Evaluating Crop Protection Container Management Programs

Container management programs have been successfully implemented in many regions of the world, but further progress can be made to increase the global coverage of such programs, to improve collection rates and to reduce the environmental footprint through greater recycling of used packaging.

Plastic waste is a significant environmental problem, especially given the potential for lasting damage to the earth and its population. The use of virgin plastic for producing more packaging containers is growing and is expected to grow further due to the increasing global population. With approximately one third of all used plastic ‘leaking’ into the environment, this has a major impact on the environment - in particular the ocean.

There are opportunities for improvements such as plastic recycling, which remains limited with an estimated 95% of plastic packaging material value being lost after its first use.

Although the volume of empty crop protection containers is only a small proportion of the total plastic and packaging waste, it needs to be managed correctly to minimize the risk of pesticides and containers negatively affecting humans and the environment.

CropLife International and its members play a key role in managing container management programs and some of them have been operating for more than 30 years.

Container Management Programs – How They Work

Collection schemes for empty crop protection containers currently operate in almost 60 countries around the world. Some of the most successful container management programs are based on multi-stakeholder projects where every step of the container life-cycle is managed. Schemes often benefit from partnerships with authorities, other industries and stakeholders. These types of local collaborations have helped grow existing programs by reducing costs, raising awareness and building knowledge between all the partners.

The organization of the programs do face management issues in different parts of the world. The classification of containers as hazardous waste is one difficulty that has been faced. This issue has been overcome in many regions by requiring that containers be triple rinsed at the farm level. Triple rinsing has led to containers being recognized as safe to be transported and recycled, reducing the amount of plastic waste that is unnecessarily incinerated or entering landfill sites.

Training and awareness-raising along the production chain are vital to promoting container management programs and to ensure knowledge sharing between authorities and industry.

It is important that container management programs be cost effective for stakeholders. This includes making it easier for farmers to return the empty containers. All stakeholders need to engage and promote the schemes and ensure that they deal with the environmental and recycling challenges.

Triple Rinsing in France

Triple-rinsing of empty containers on-farm is a key element of the French program– containers are then considered to be safe (nonhazardous), allowing collection and recycling. Triple-rinsed containers are transported by the user (farmer) to the retailer, where the containers are collected by ADIVALOR and taken to a recycling facility. ADIVALOR conducts regular sample tests to verify if the containers are rinsed correctly. Continued efforts to promote compliance and raise awareness of the need for triple rinsing is done via dealers, distributors, and technical institutes that provide information and training to farmers and farmer cooperatives.

High Rate of Collection in Brazil

The Brazilian container management program was highlighted as being particularly successful, with the highest percentage of collected containers. This is partly due to the involvement of the authorities, who share the responsibility of the waste management and enforce a prescription system that requires the farmer to return the containers or pay a fine.

Cooperation with Other Sectors in Canada

The CleanFarms scheme recovers crop protection containers as well as fertilizer containers. Fertilizer containers were included when it was discovered that they make up a significant part of on-farm plastic in Canada. CleanFarms conducts a secondary wash of the containers after collection and measures the residue levels in the shredded plastic to ensure compliance with international limits allowing them to be shipping as non-hazardous recyclable material into the USA.

Removing Barriers to the Recycling of Crop Protection Containers

Given the current challenges in managing plastic waste, a key target for authorities and industry must be to maximize the recycling of collected containers. In some cases, this will require national authorities to review their policies on how to deal with crop protection containers. Crop protection containers need to be considered as ‘safe’. The United Nations Food and Agriculture Organization and the World Health Organization recommend that countries should classify properly rinsed containers that have been inspected as non-hazardous to simplify the transport and recycling process. This helps reduce the costs of the management scheme and provides an incentive for farmers to rinse containers, resulting in an increased rate of collection of used containers.

“Triple rinsing is key to ensure that used crop protection containers can be considered as ‘safe’ to simplify the transport and recycling process.”

It is therefore essential that training and education continue – in particular to ensure that farmers are aware of all the benefits. Triple rinsing not only reduces the risk for users, the environment and the local community, it also has an economic benefit to the farmer and ensures that the crop protection product is not wasted.

While the importance of triple rinsing from a safety and recycling viewpoint is vital, showing that the farmer reaps a benefit will also improve the understanding of why a farmer would want to triple rinse.

Data on the rinsability of a wide range of packaging and formulations has been carried out by the European Crop Protection Association (ECPA, 2003). In an analysis of data from 180 rinsed containers, an average rinsing effectiveness achieved using either manual triple rinsing or integrated pressure rinsing was 99.992%.

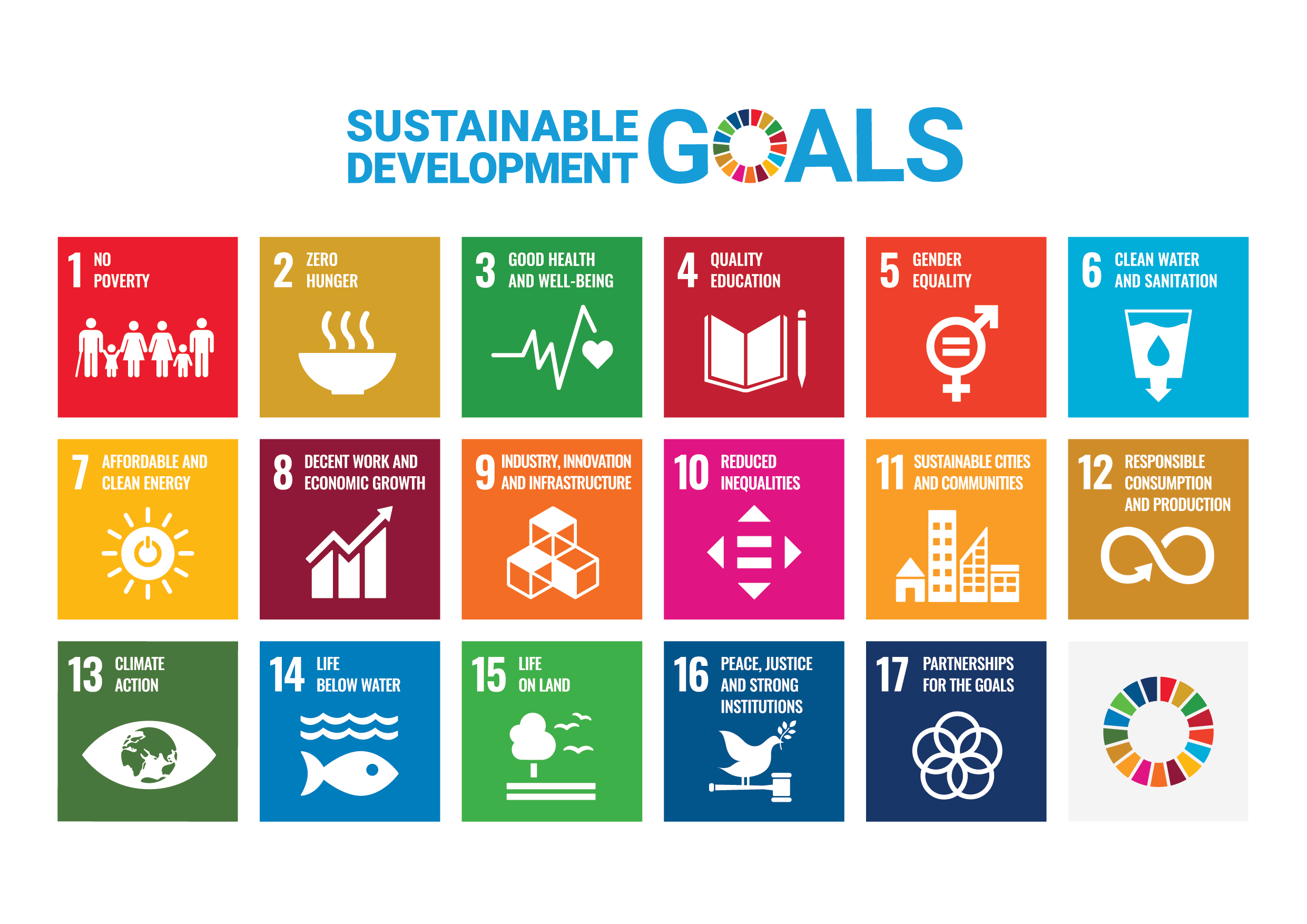

UN Sustainable Development Goals (SDGs)

From an environmental and health perspective, moving away from the linear ‘take-make-dispose’ model of consumption and adopting a more circular approach are essential in order to achieve the UN Sustainable Development Goal on Sustainable Consumption and Production (SDG 12).

In addition to improving resource efficiency, recycling would reduce greenhouse gas emissions (SDG 13), ocean pollution (SDG 14), health hazards for workers handling the containers (SDGs 3 and 8), and leakage in the natural environment (SDGs 3 and 6), especially in developing countries.

To fulfill the aims of the relevant Sustainability Development Goals, indicators need to be developed that will help all stakeholders to track progress.

“Cooperation will be essential for the container management programs to achieve the target to increase the rate of collection and recycling of used containers.”

Options for Recycle and Reuse

Plastic collected in container management programs can be recycled into a range of products. While crop protection containers can be reused as packaging for new pesticides, this is not a major use. The plastic is most commonly used in applications with lower demands like plant pots, outdoor furniture, fencing and fencing posts, garden decking, traffic bollards as well as road surfacing.

“There are many options for the use of recycled plastic from crop protection containers. It's essential that programs are in place to collect and process the material into useful products.”